The exhaust gas heat exchanger for heat pump drying is a device used to recover and reuse the waste heat generated during the drying process. It can improve energy efficiency, reduce operating costs, and minimize environmental impact, making it an indispensable part of modern industry.

working principle:

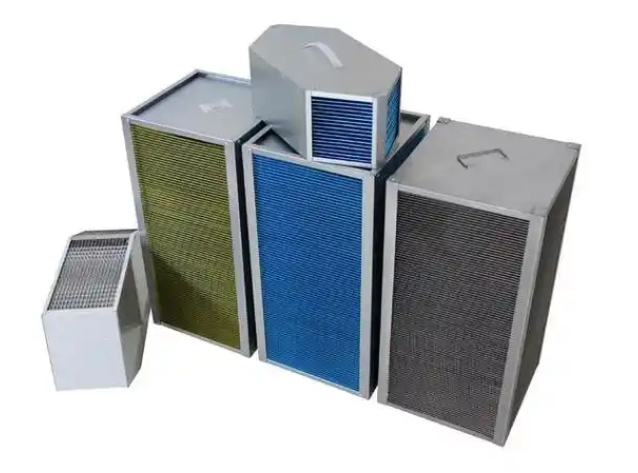

Plate heat exchangers are composed of heat exchange cores, guide vanes, fixed frames, etc. They adopt cross flow, counter flow, or cross counter flow structures to ensure that the two airflows do not mix and to avoid the transfer of odors and moisture. This design improves the efficiency and reliability of heat exchange. When there is a temperature difference between two airflows, they will exchange heat through a heat-conducting plate. The hotter side transfers heat to the cooler side to achieve energy recovery. Plate heat exchangers adopt a modular structure, with low maintenance costs and easy use. According to different air flow channels, it can be divided into cross flow, counter flow, and cross counter flow types to meet different application requirements.

Plate heat exchangers are not only used in heat pump drying systems, but also widely used in various industries such as HVAC, communication, power, textile, automotive, food, medical, agriculture, animal husbandry, etc., for ventilation, energy recovery, cooling, preheating, dehumidification, and waste heat recovery.

Exhaust gas heat exchanger for heat pump drying

Deja una respuesta

Deja una respuesta

Debes iniciar sesión para comentar.

Sobre el Autor