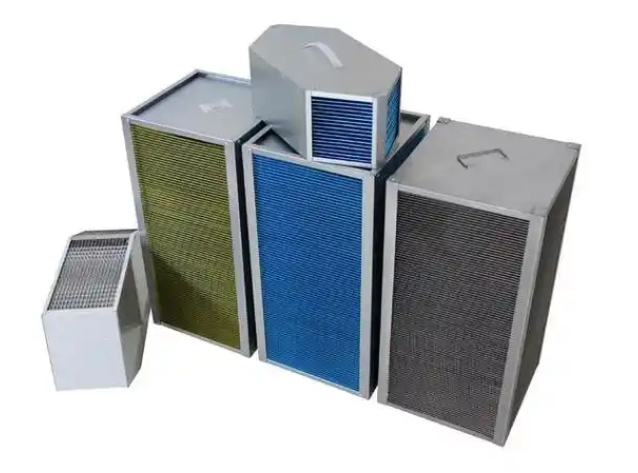

The kiln waste heat recovery and reuse system aims to fully utilize the high-temperature heat in the kiln exhaust gas, and achieve a win-win situation of energy conservation and environmental protection through gas stainless steel cross flow heat exchangers. The core of this solution lies in the use of a stainless steel cross flow heat exchanger, which efficiently exchanges heat between high-temperature exhaust gas and cold air, generating hot air that can be reused.

Working principle: The exhaust gas and cold air flow in a cross flow manner inside the heat exchanger and transfer heat through the stainless steel plate wall. After releasing heat from exhaust gas, it is discharged. Cold air absorbs the heat and heats up into hot air, which is suitable for scenarios such as assisting combustion, preheating materials, or heating.

Advantages:

Efficient heat transfer: The cross flow design ensures a heat transfer efficiency of 60% -80%.

Strong durability: Stainless steel material is resistant to high temperatures and corrosion, and can adapt to complex exhaust environments.

Flexible application: Hot air can be directly fed back to the kiln or used for other processes, with significant energy savings.

System process: Kiln exhaust gas → Pre treatment (such as dust removal) → Stainless steel heat exchanger → Hot air output → Secondary utilization.

This solution is simple and reliable, with a short investment return cycle, making it an ideal choice for kiln waste heat recovery, helping enterprises reduce energy consumption and improve efficiency.