With the further development of China's economy, the use of green energy will be more and more extensive. Heat pump dehumidification dryers with plate type obvious heat recovery function have developed rapidly in recent years and have been widely used in the Yangtze River basin, southwest China and South China.

The unit using the inverse cano principle at the same time, combined with efficient heat recovery technology, in the whole drying dehumidifying process, through the duct the wet air within the chamber connected to the host using the sensible heat plate heat collector recovery of the sensible heat and latent heat of hot and humid air, thermal recycling, greatly improve the performance of the host, improve the drying speed and material quality. The waste heat can not only improve the performance of the unit, but also reduce the thermal pollution to the environment and alleviate the urban heat island effect.

The heat pump drying heat recovery system is not only used in the mud drying system, but also widely used in many other drying industries. It has the characteristics of good drying quality and high degree of automation, and is the best choice product for energy saving, green and environmental protection in the modern drying industry.

Heat pump dryers with and without heat recovery working principle

When the heat pump dryer dries the air, the air forms a closed cycle between the drying chamber and the equipment. The evaporator's heat absorption function is used to cool and dehumidify the hot and humid air, and the condenser's heat release function is used to heat the dry cold air, so as to achieve the effect of cycle dehumidification and drying.

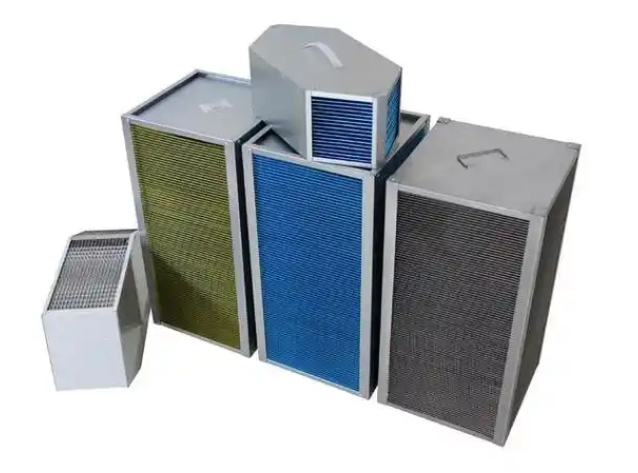

The main difference between heat recovery function and heat pump dryers without heat recovery function lies in the different air circulation modes. The former is equipped with plate type sensible heat exchanger, which plays the function of pre-cooling and preheating in the air circulation process, reducing the load of compressor operation and achieving the purpose of energy saving.

Heat pump drying system operation mode

Energy saving analysis of heat recovery

Taking a heat pump dryer as an example, the air temperature of drying is designed to be 65℃, the relative humidity is 30%, the circulating air temperature is 65℃, the temperature before passing through the evaporator is 65℃, and the temperature after evaporation cooling is 35℃. The condenser needs to heat the air of 35℃ to 65℃ before it can be used.

After matching with BXB500-400-3.5 heat exchanger, 35℃ return air absorbs heat from exhaust air after passing through plate heat exchanger, and the temperature rises to 46.6℃. The condenser only needs to heat the air from 46.6℃ to 65℃ to meet the use requirements, greatly reducing the load of evaporator and condenser, thus reducing the power of the whole machine, achieving the purpose of energy saving.

Energy saving analysis of heat recovery

Selection and economic calculation

We are very glad to show you the calculation and selection software of plate heat exchanger jointly developed by us and Tsinghua University. If you need, please contact us!