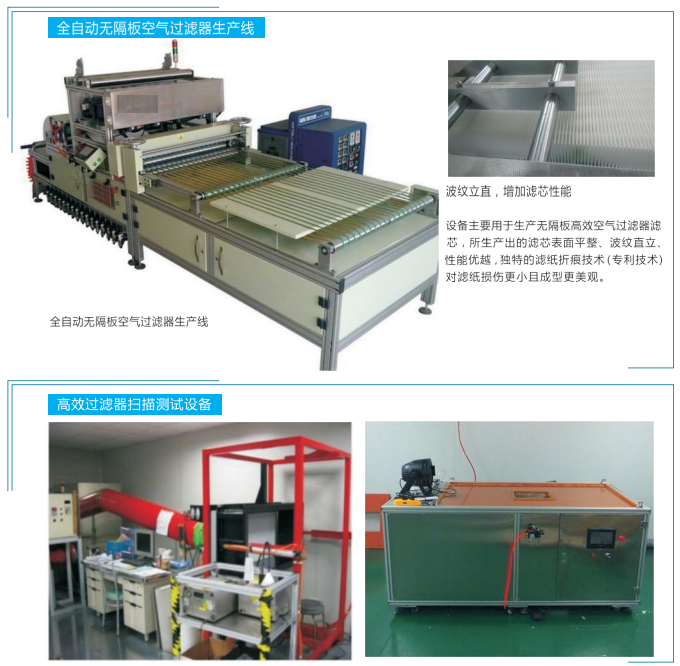

Fully automatic non partition air filter production line

The fully automatic non partition air filter production line is a highly automated production system, typically used to produce high-performance air filters, widely used in industrial, commercial, and household air purification equipment. Its core feature is the use of a non partition design to improve the filtration efficiency of the air filter and reduce the resistance of air flow.

Main features:

Partition free design: Traditional air filters typically use partitions to separate the filter material layer, while partition free design can effectively reduce obstacles to air flow, thereby improving filtration efficiency and reducing energy consumption.

Fully automated operation: From raw material cutting, filter material assembly, to finished product packaging, the production line achieves full automation, reduces manual intervention, and improves production efficiency and consistency.

High precision control system: By integrating advanced automation control systems and sensors, it ensures precise control of the production process and achieves high-quality filter products.

Fast switching and flexibility: The production line supports the production of filters of different specifications and types, and can quickly switch production modes to meet the needs of different customers.

Efficient production capacity: Design efficient processes and modular systems that can meet large-scale production requirements and ensure stable product quality.

Sobre o autor